In recent years, China has become the undisputed global hub for OEM and ODM beauty device manufacturing. From home use facial devices to advanced RF, EMS, IPL, and multi-function beauty equipment, an increasing number of international brands are sourcing their products from Chinese manufacturers.

This trend is not driven by cost alone. Brands across North America, Europe, the Middle East, and Asia-Pacific are choosing China for its manufacturing ecosystem, technical expertise, speed to market, and scalability. For both emerging beauty startups and established global brands, OEM partnerships in China have become a strategic advantage.

So why exactly are more brands choosing OEM beauty device manufacturers in China today? This article explores the key reasons behind this shift and what buyers should understand when sourcing from the Chinese beauty device industry.

The Global Growth of OEM Beauty Device Sourcing

As the home beauty device market expands, brands are under increasing pressure to innovate faster, control costs, and meet diverse regulatory requirements. Developing proprietary manufacturing capabilities in-house is often impractical, especially for brands focused on marketing, distribution, and customer experience.

OEM manufacturing allows brands to outsource production while maintaining control over branding, specifications, and market positioning. China’s manufacturing sector has evolved to support this model at scale, making it the preferred sourcing destination for beauty device OEM projects worldwide.

China’s Complete Beauty Device Manufacturing Ecosystem

One of China’s greatest advantages lies in its highly integrated supply chain. Unlike regions where components must be sourced from multiple countries, China offers a complete ecosystem within close geographic proximity.

Key components such as PCBs, motors, batteries, LEDs, housings, and packaging materials are readily available. This concentration reduces lead times, lowers logistics costs, and allows manufacturers to respond quickly to design changes or market feedback.

For beauty devices that require precise integration of electronics, materials, and industrial design, this ecosystem is a critical factor in achieving consistent quality and efficiency.

Strong R&D Capabilities and Technology Adoption

Modern Chinese beauty device manufacturers are no longer purely production-focused. Many have invested heavily in research and development, employing engineers specializing in electronics, firmware, industrial design, and skin-contact materials.

This has enabled Chinese OEM factories to master complex technologies such as RF energy control, EMS current modulation, IPL optical systems, and LED wavelength calibration. As a result, they can support both OEM (build-to-spec) and ODM (design-to-market) projects.

For brands, this means faster access to mature technologies without the need for long internal development cycles.

Faster Time to Market for Beauty Brands

Speed is a decisive factor in the beauty industry, where trends evolve rapidly and product life cycles are short. Chinese OEM manufacturers are known for their ability to move from concept to mass production quickly.

With in-house tooling, rapid prototyping, and experienced project management teams, many factories can deliver functional samples in weeks rather than months. This agility allows brands to test markets, respond to consumer feedback, and launch new products ahead of competitors.

For private label and DTC brands, this speed often determines success or failure.

Cost Efficiency Beyond Labor Savings

While labor costs in China have increased over time, cost efficiency remains a key advantage—but not simply because of wages. Cost savings come from economies of scale, optimized production processes, and supply chain integration.

High-volume component sourcing reduces material costs, while automated assembly lines improve consistency and reduce defect rates. These efficiencies allow OEM manufacturers to offer competitive pricing without compromising quality.

For brands, this translates into healthier margins or greater flexibility in pricing strategies.

Advanced Quality Control and Manufacturing Standards

Quality perception is often a concern for first-time buyers sourcing from China. However, leading beauty device manufacturers operate under strict quality management systems, often aligned with international standards.

Processes such as incoming material inspection, in-line quality checks, functional testing, and aging tests are standard practice. Many factories also support third-party inspections and audits.

As global competition increases, Chinese OEM manufacturers understand that consistent quality is essential for long-term partnerships, not just short-term orders.

OEM and ODM Flexibility for Different Brand Needs

One of the main reasons brands choose China is the flexibility offered by OEM and ODM manufacturing models.

OEM services allow brands to provide their own designs and specifications while leveraging the factory’s production capabilities. ODM services, on the other hand, enable brands to customize existing designs or co-develop new products with minimal upfront investment.

This flexibility is particularly valuable for brands at different stages of growth, from startups launching their first product to established companies expanding their portfolios.

Experience with Global Compliance and Certifications

Beauty devices are subject to varying regulatory requirements across markets. Chinese OEM manufacturers with export experience are well-versed in supporting certifications such as CE, FCC, RoHS, and other regional compliance standards.

Rather than navigating these processes alone, brands benefit from manufacturers who understand testing requirements, documentation, and compliance timelines. This experience reduces risk and accelerates market entry.

For brands targeting multiple regions, working with a compliance-aware OEM partner is a significant advantage.

Customization and Branding Capabilities

Modern beauty device buyers expect more than generic products. Customization has become a core requirement, and Chinese OEM manufacturers excel in this area.

Options typically include industrial design modifications, surface finishes, color customization, logo application, packaging design, and user manual localization. Some manufacturers also support software customization and app integration.

These capabilities allow brands to create differentiated products that align with their identity and target audience.

Scalability for Growing Brands

Scalability is a critical consideration for brands planning long-term growth. Chinese OEM factories are designed to handle both small trial orders and large-scale mass production.

This scalability enables brands to start with conservative order quantities, test market response, and ramp up production as demand grows—without switching suppliers.

For fast-growing beauty brands, this continuity reduces operational complexity and supports sustainable expansion.

Global Trust Built Through Long-Term Partnerships

Over the past two decades, many Chinese beauty device manufacturers have built long-term relationships with international clients. These partnerships are based on mutual understanding, technical collaboration, and continuous improvement.

As communication practices, transparency, and project management have improved, trust between global brands and Chinese OEM suppliers has strengthened.

This trust is a key reason why repeat orders and long-term contracts are common in the beauty device industry.

Addressing Common Buyer Concerns

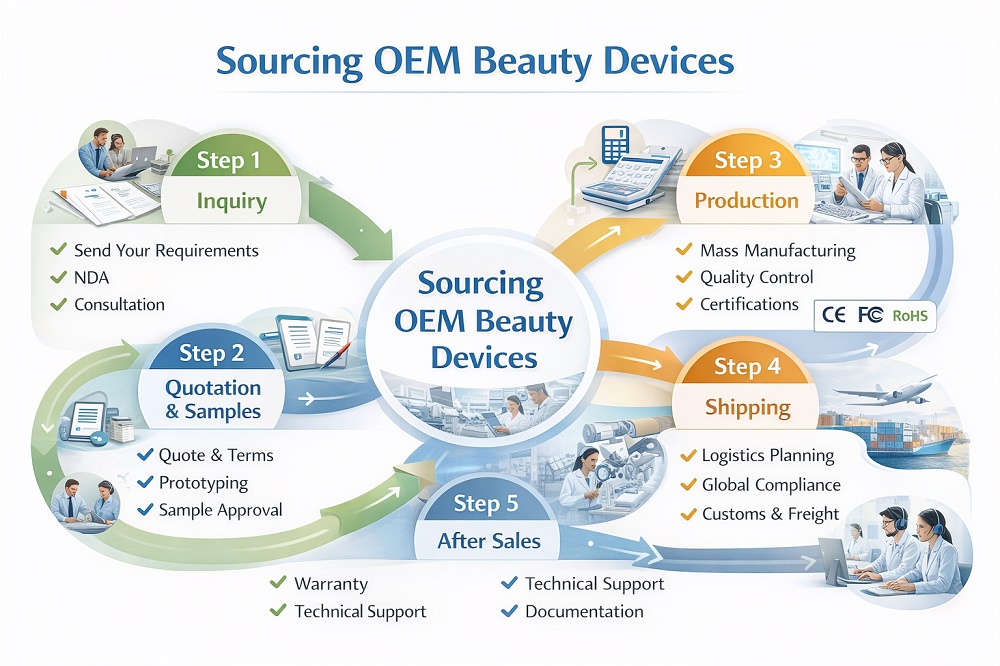

Despite the advantages, buyers often have concerns about intellectual property protection, communication barriers, and after-sales support. Reputable OEM manufacturers address these issues through NDAs, clear project documentation, bilingual sales teams, and structured after-sales processes.

Choosing the right partner is essential. Brands that conduct proper due diligence, factory audits, and pilot projects are far more likely to achieve successful outcomes.

The Strategic Role of China in the Future Beauty Device Market

As technology continues to evolve and consumer expectations rise, the role of Chinese OEM manufacturers will become even more significant. Integration of smart features, AI-driven personalization, and sustainable design will further strengthen China’s position as a global manufacturing leader.

Rather than simply serving as production centers, many OEM factories are becoming innovation partners, contributing ideas, market insights, and technical solutions.

For brands looking to stay competitive, leveraging this expertise is no longer optional—it is strategic.

Conclusion: A Smart Choice for Modern Beauty Brands

More brands are choosing OEM beauty device manufacturers in China because the advantages go far beyond cost savings. From complete supply chains and strong R&D to speed, scalability, and customization, China offers a comprehensive solution for modern beauty device sourcing.

For brands willing to invest in the right partnerships, OEM manufacturing in China provides the foundation for innovation, differentiation, and long-term growth in a highly competitive global market.

As the home beauty device industry continues to expand, China’s role as a trusted OEM manufacturing hub is set to grow even stronger.